Why Innovative Eco-Friendly Building Materials Matter Now

Embodied carbon is the climate cost of extraction, manufacturing, transport, and construction. Innovative eco-friendly building materials slash that footprint through recycled content, biobased fibers, and clean energy production. Ask for Environmental Product Declarations to compare options and track measurable impact.

Why Innovative Eco-Friendly Building Materials Matter Now

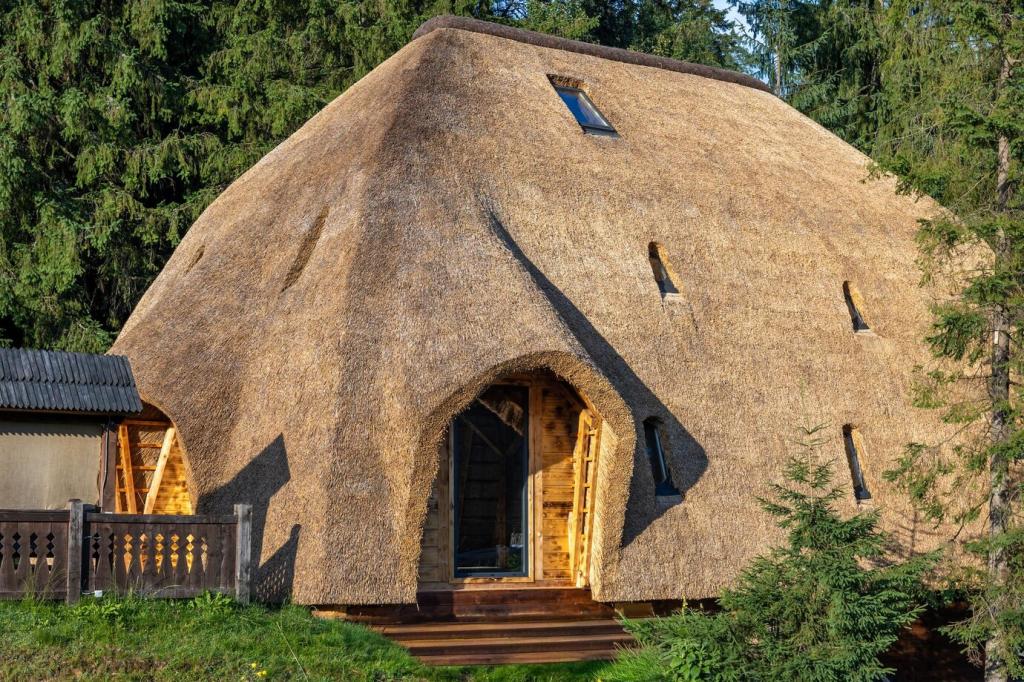

From low-VOC finishes to breathable plasters, better materials can improve indoor air quality and comfort. Lime, clay, and wood regulate humidity and reduce stale-air headaches. When materials help the building breathe, occupants notice fewer irritants, steadier temperatures, and calmer, quieter rooms.

Why Innovative Eco-Friendly Building Materials Matter Now

Eco-friendly does not mean fragile. Mass timber resists fire by charring predictably, lime-based mortars self-heal microcracks, and dense cellulose insulation remains effective across seasons. Beauty grows with time: wood patinas, limewash deepens, and reclaimed surfaces carry stories worth preserving.

Why Innovative Eco-Friendly Building Materials Matter Now

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.